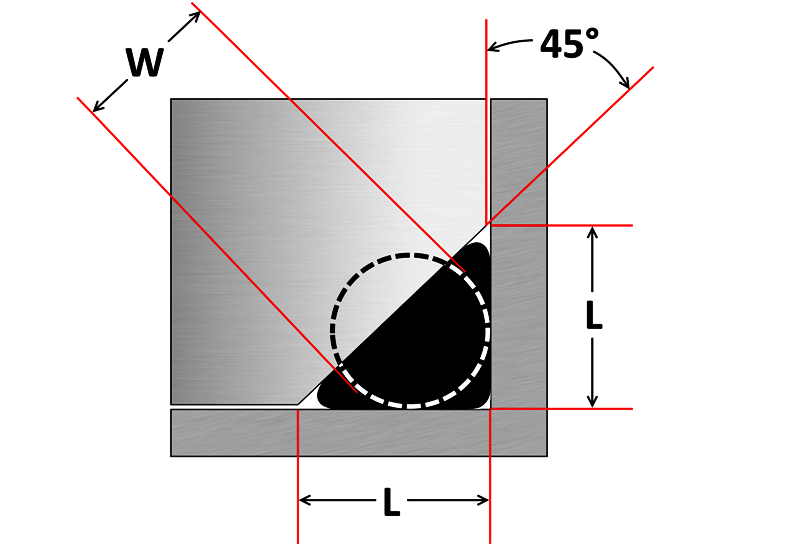

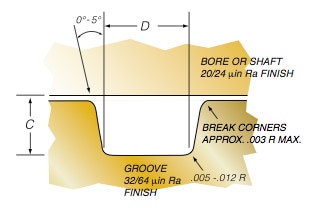

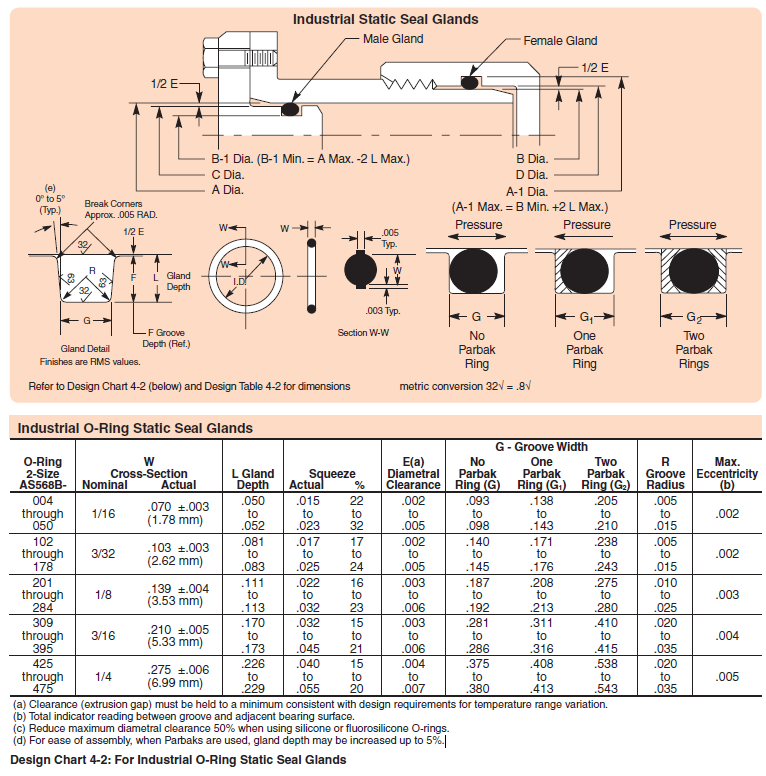

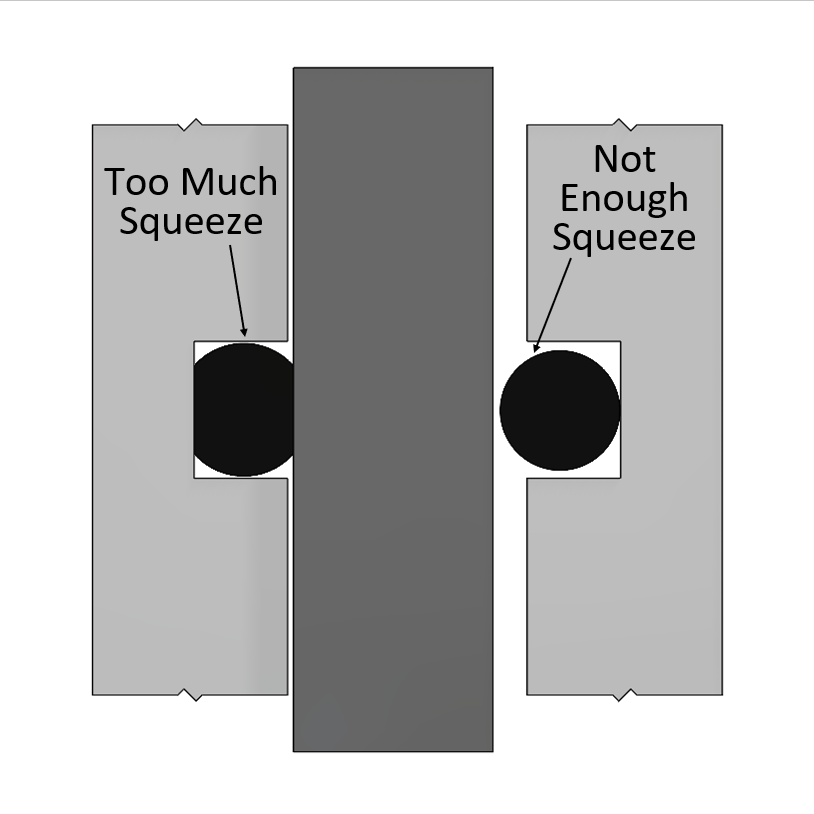

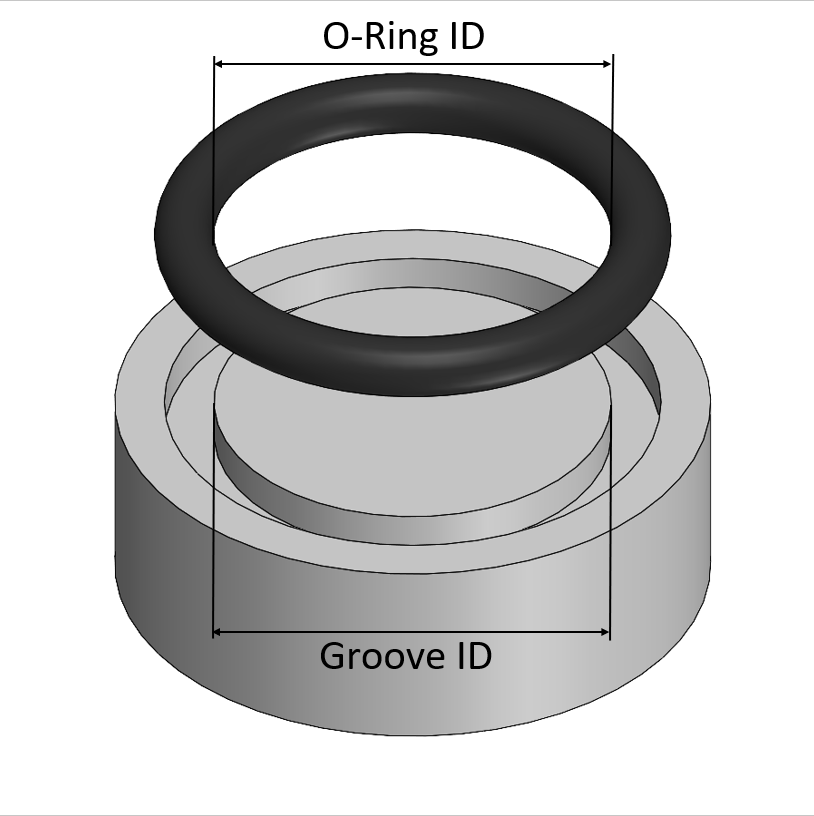

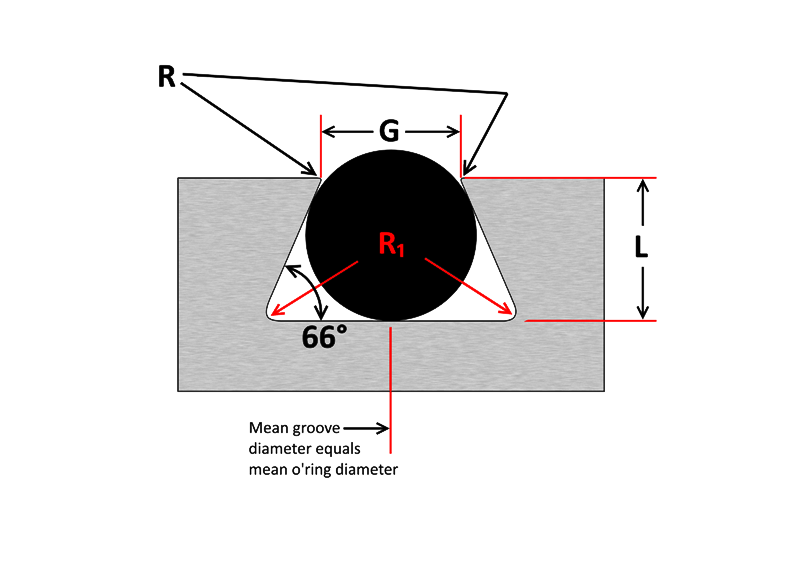

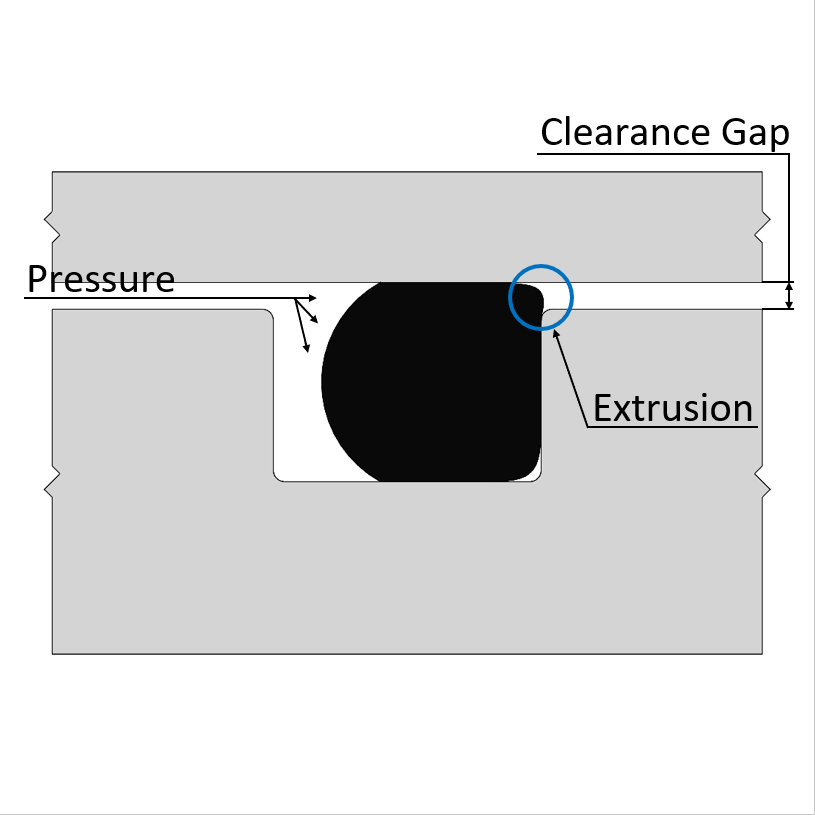

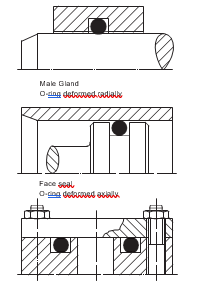

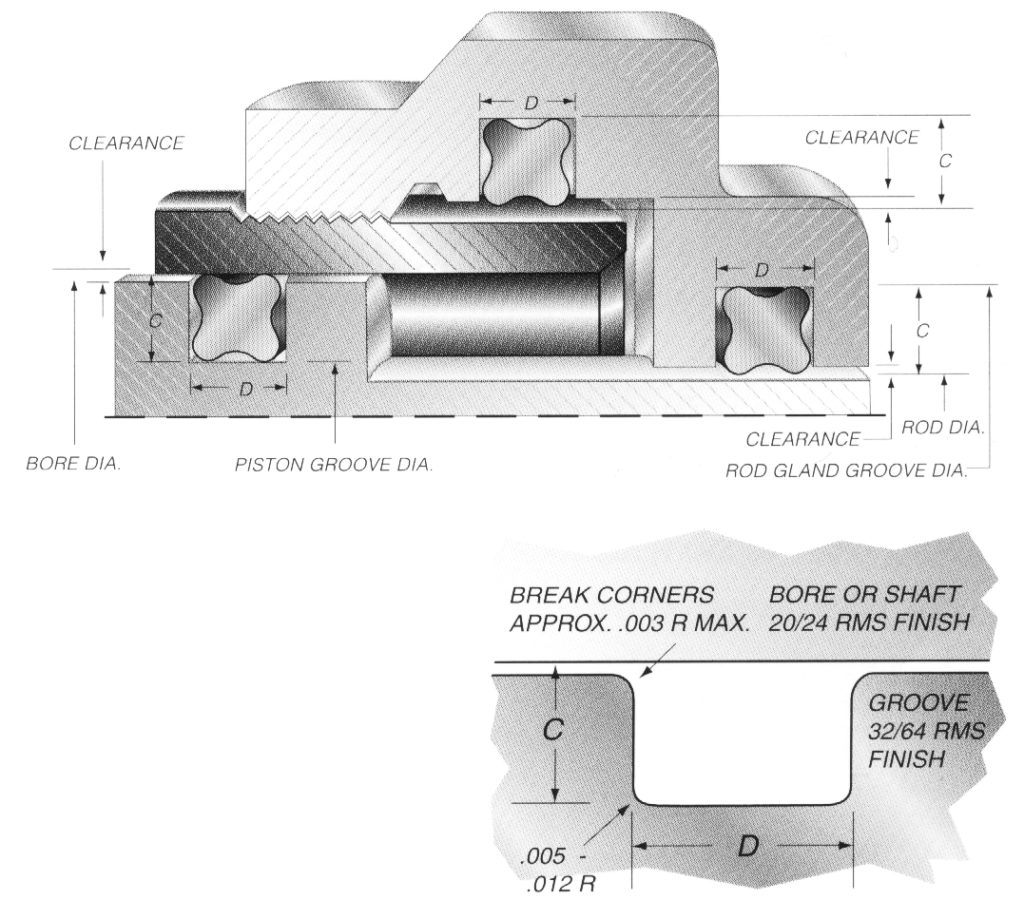

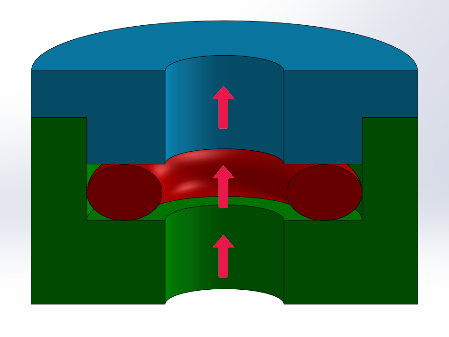

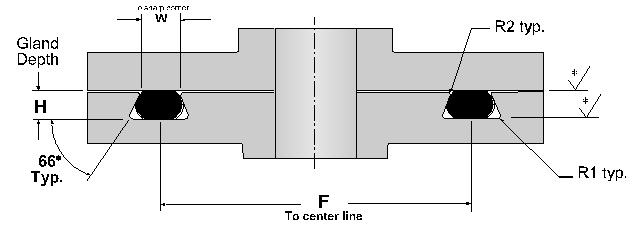

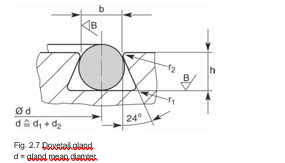

O'ring Groove Design As important as the o'ring seal itself is the groove that the o'ring seats into The groove must be designed to accommodate not just the o'ring size, but also its intended usage;Dovetail grooves are used to hold the Oring in place during installation or maintenance This groove design is relatively uncommon as it is expensive to machine and should not be used unless absolutely required The dovetail groove construction is only recommended for Orings with cross sections of 139 inch (3,53 mm) and largerORing Gland General Design Considerations ORing Squeeze Compression (ORing C/S) Gland Depth / (ORing C/S) • Face Seal 30% • Static Male/Female 15% • Reciprocating 10% • Rotary 010% ORing Installed Stretch (Groove Diameter) (ORing ID)(ORing ID) •

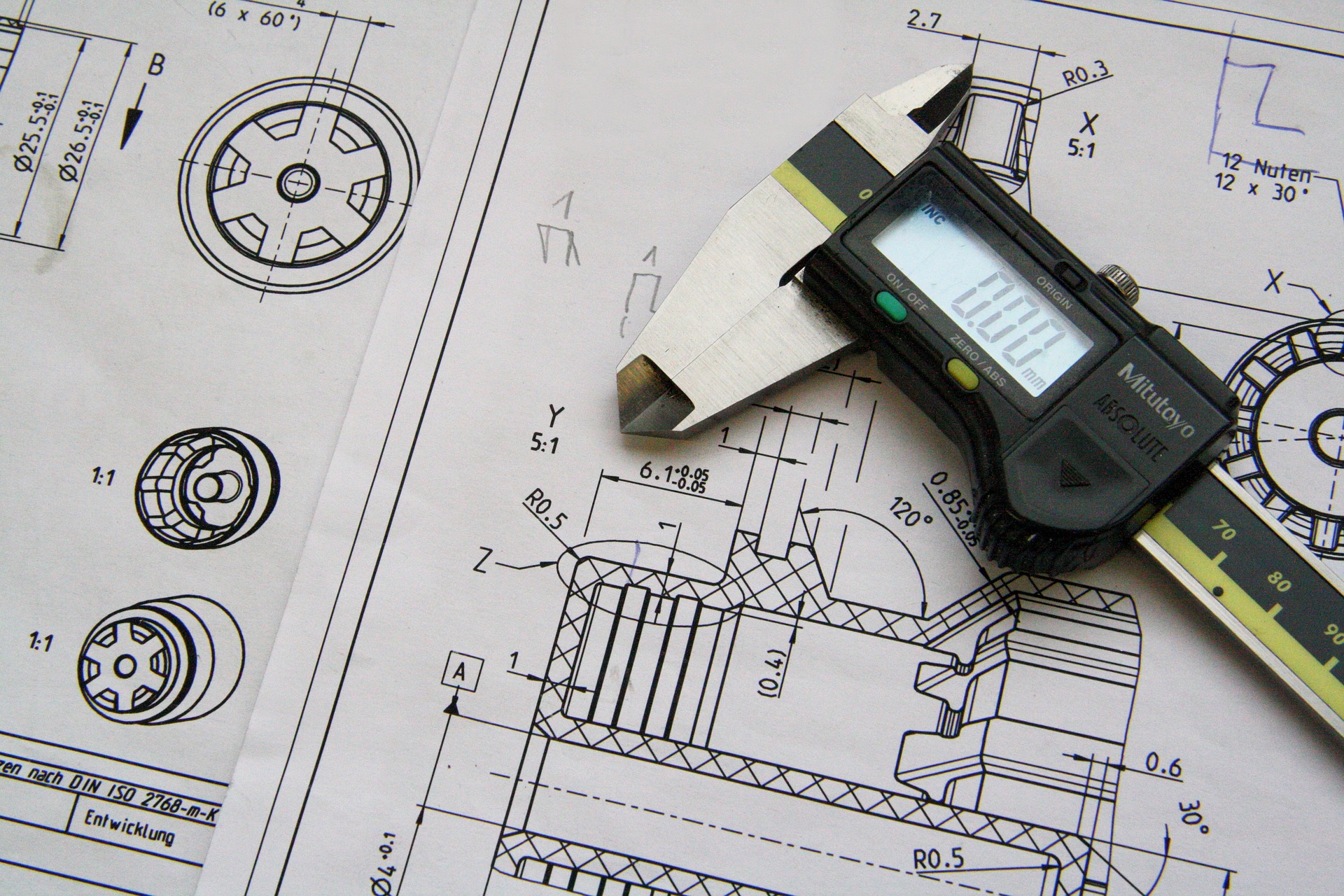

4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics

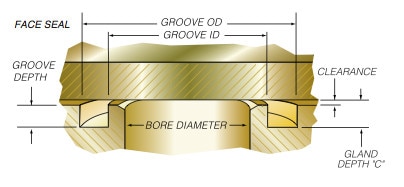

O-ring groove design face seal

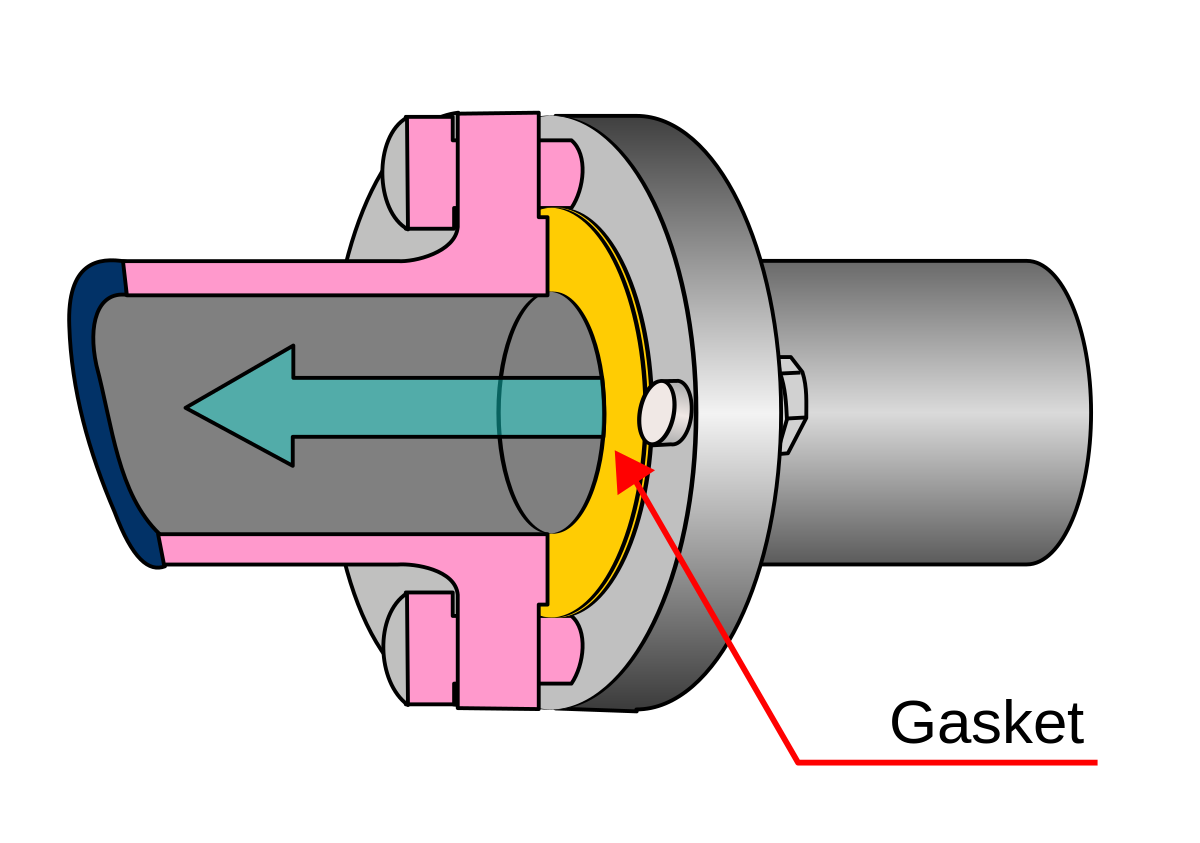

O-ring groove design face seal-Be it dynamic or static operation, radial or axial loading, vacuum or high pressureGroove design guide for static oring face seals provides default recommendations on width, depth, diameter and more for basic applications Oring face seals are used in a variety of applications, including bolted flanges or removable lids Simple selection tool to

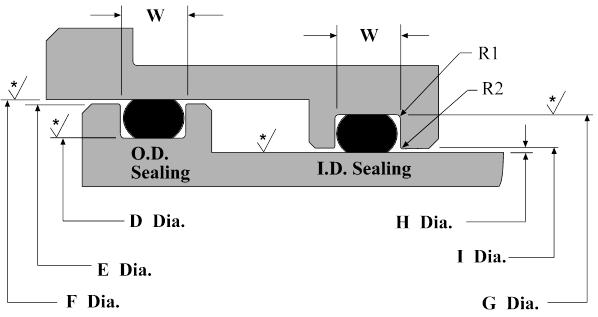

Quad Ring Groove Design Daemar Inc

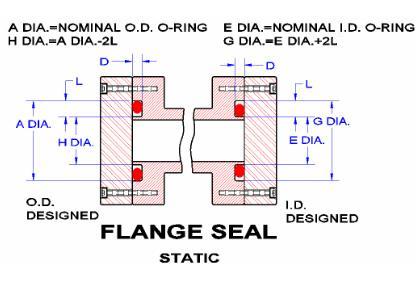

The groove design allows the Oring to be retained in the face seal during assembly and maintenance This is beneficial for special applications where the Oring has to be fixed by the groove eg a lid which opens regularly Bosstail The Oring is used for sealing straight thread tube fittings in a bossRubber Seals, Sealing Devices & ORing Seal Design AppleFace Seal Flange ORing Groove Design Chart Dovetail Flange ORing Groove Design Chart XRing and High Performance ORing XRing Seals and high performance ORing material groove design follows the same principals as basic ORing applications, although require even more attention to design adjustments for specific application environments

If you are designing a face seal, select the ORing with an inside diameter which will position the ORing on the side of the groove opposite the pressure Click here for more information on face seal groove design Note the ORing inside diameter for the next step Calculate the Seal Stretch Using Equation 1, calculate the installed seal stretch I am looking for some design recommendations on oring groove design to help retain an oring used in a face seal application With the standard rectangular groove the oring does not stay in the groove reliably and it can not be checked after assemblyMechanical / Heavy Duty Face Seals 'O' Ring Kits Circlip Kits Splicing Kits 'O' Ring Cord BARNWELL 'O' RINGS 3 effect a seal in a groove size of almost equal volume It is BARNWELL 'O' RINGS 4 The 'O' Ring The 'O' Ring or Toroidal Seal is a simple, versatile and economical

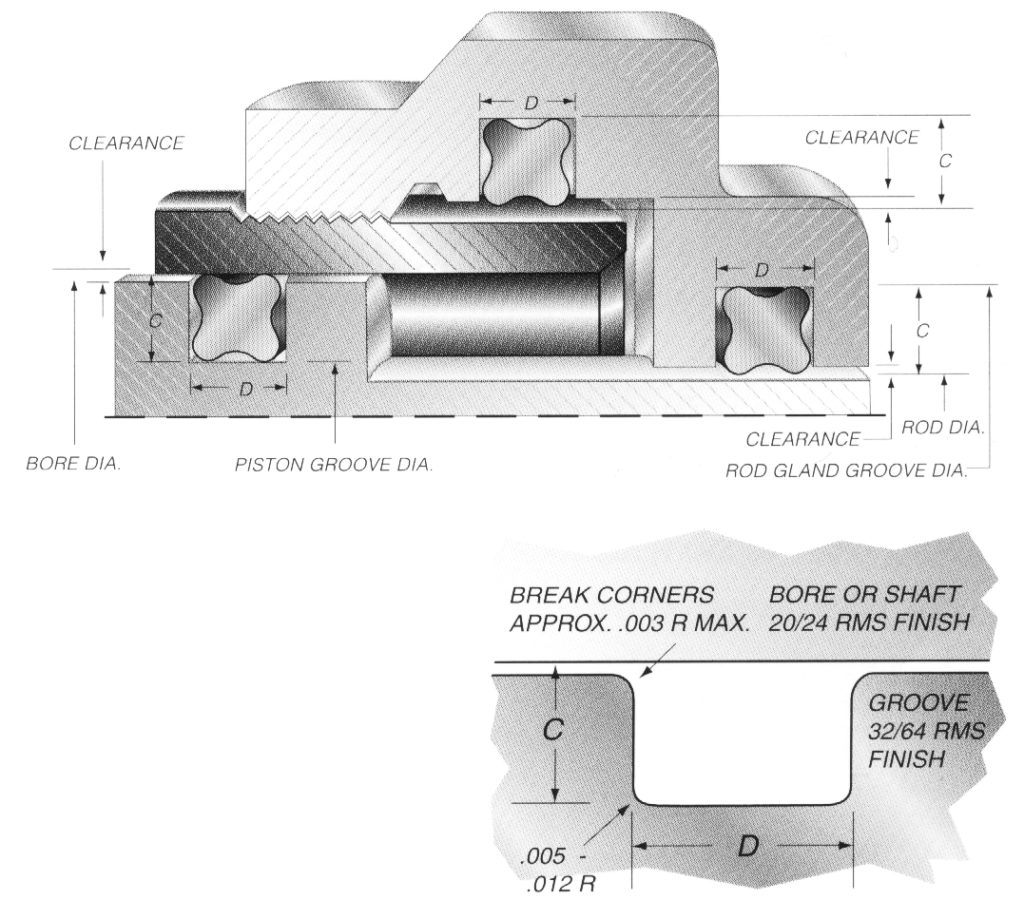

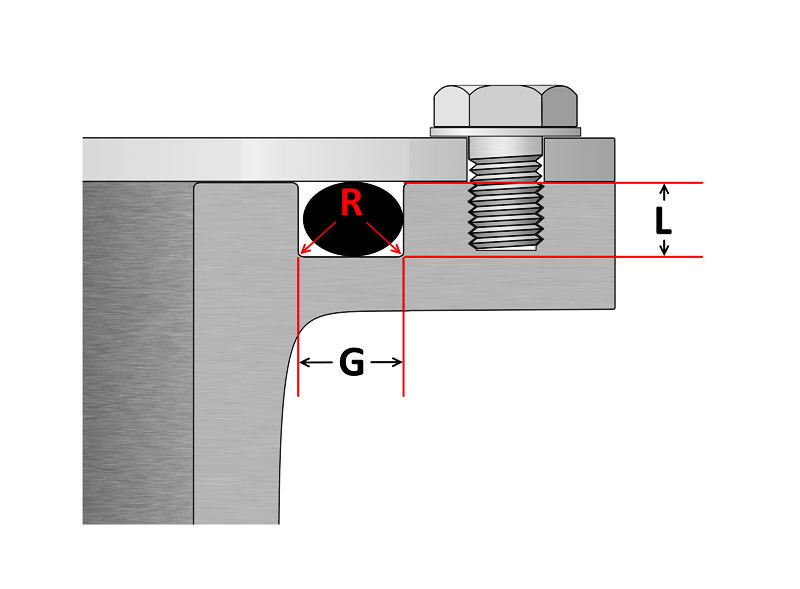

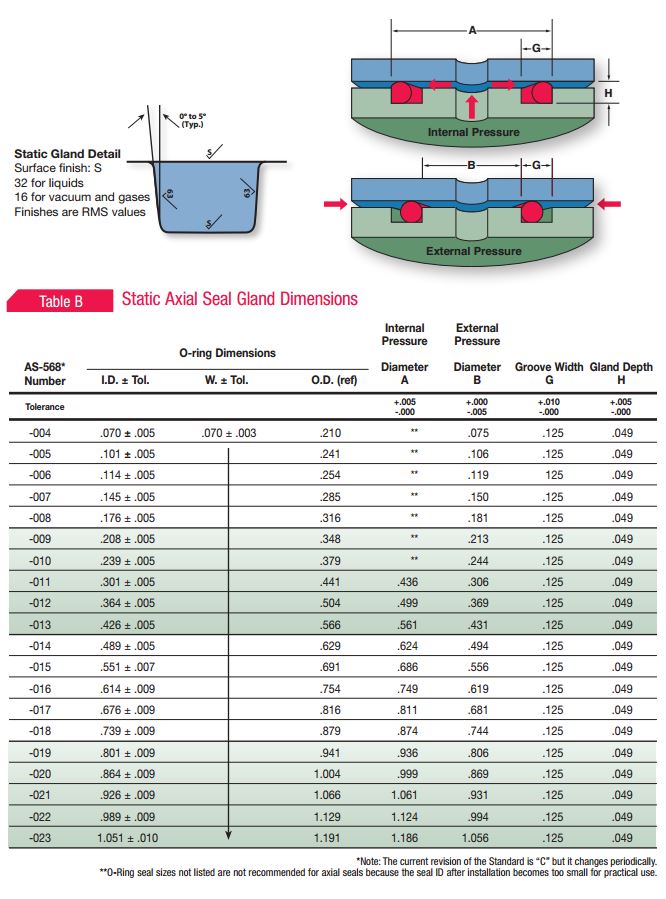

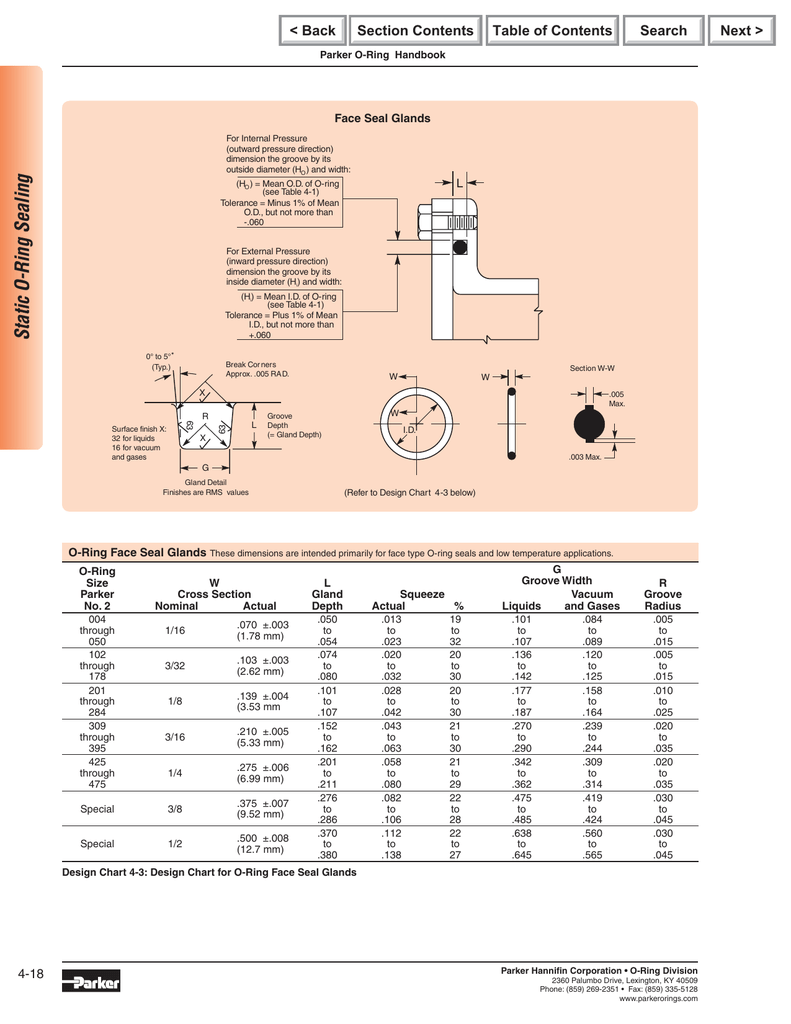

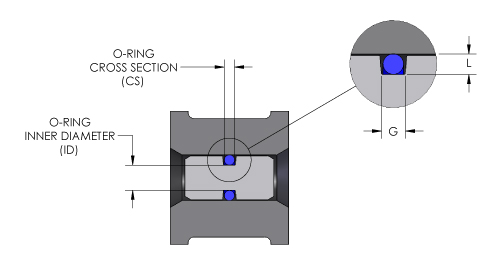

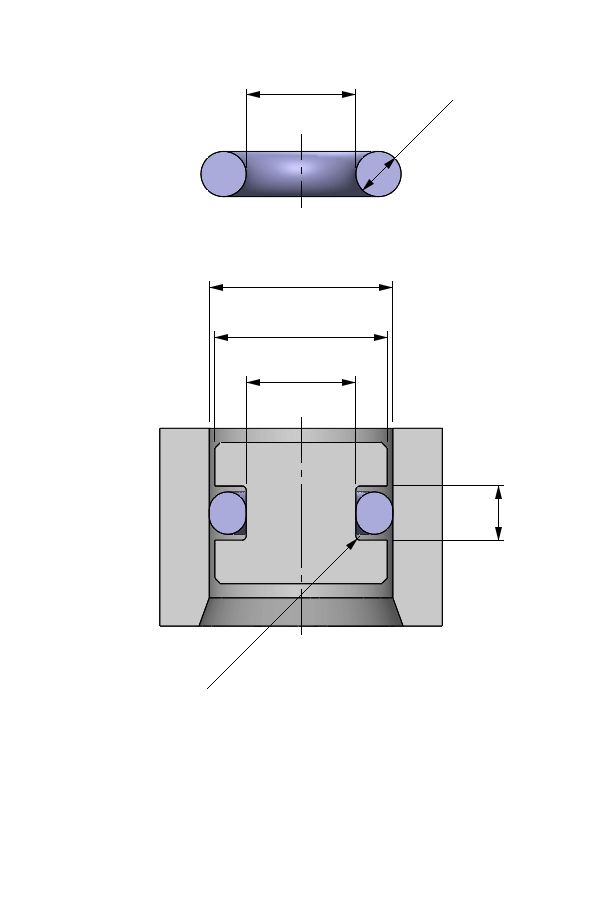

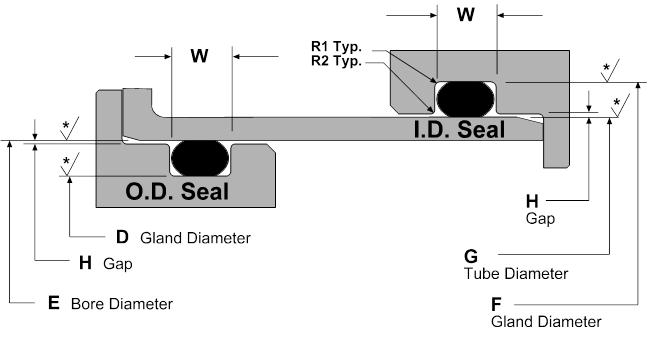

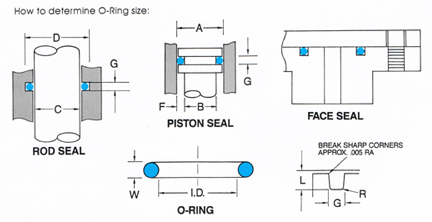

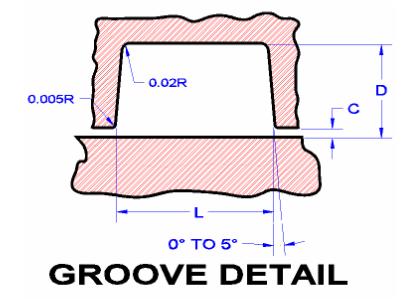

ORing Face Seal Glands These dimensions are intended primarily for face type Oring seals and low temperature applications ORing Size Parker No 2 W Cross Section Nominal Actual L Gland Depth Squeeze Actual % G Groove Width R Groove Liquids Radius Vacuum and Gases 004 through 050 1/ ±003 (178 mm)050 to to023 19 toORing Design Considerations What to Know About ORing Squeeze, Stretch, Compression, and More Our oring groove design guides list default oring groove dimensions for the most basic applications and are intended to be used with the following oring groove design considerations to engineer on oring gland to optimize specific application performanceAS568B STANDARD ORING GROOVE DESIGN Contact Us For Assistance Or Samples Click Here and contact us today to receive a quote or if you have any questions regarding sizing × Dismiss alert The three main types of standard groove designs are Industrial Static also called Radial, Industrial Reciprocating also called Dynamic, and Face Seals also

1

O Ring Groove Design Seal Design Inc

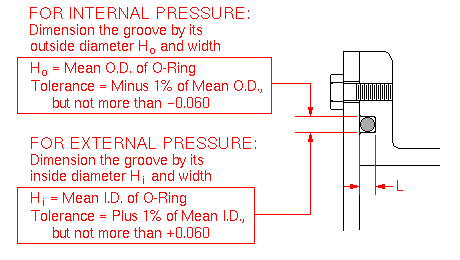

DETERMINING ORING CROSS SECTION Face Seal 101 006/ooo GROOVE ÓEPTH z 178 010 —ooo GROOVE IDTH MAXIMUM DISTORTION AND FLEX BETWEEN SEALING SURFACES 007" Á6012 ooo/—060 GROOVE OD 006" 007" 013" 052" 8 210" Quantify all factors that can reduce nominal squeeze on ORing cross section, — Maximum groove depth can vary fromSuggested Groove Design for Quattro Seals™ Due to their unique fourlobed geometry, grooves for Quattro Seals are different than those for ORings In general, Quattro Seal grooves are deeper, as less squeeze is required to affect a positive seal Quattro Seal grooves are also narrower due to their ability to resist "spiral failureHo=Mean OD of Oring Tol=1% of Mean OD not > 060 Groove ID (Hi) For External Pressure Dimension the groove by it's ID and width Hi=Mean ID of Oring Tol=1% of Mean ID Not > 060 Face Seal Gland These dimensions are intended primarily for face type seals

O Ring Groove Design Sealing Australia

1

Tested in face type Oring seals using grooves that provided 15%, 30% and 50% compression For vertical Oring applications (as a chamber), it is desirable to use an undercut groove similar to that shown in Figure 1 The Oring is held firmly in place and has no tendency to drop out of the groove when the chamber is open Figure 1AS568B CS Depth Inches % Liquids Gases Radius004 to050 Oring face seal connections tube fittings are according to SAE J1453 and ISO standards, Surface finish acceptance criteria for Oring face seal groove design connection (typical for all styles) very important O ring groove dimensions drawing a Pitch diameter

O Ring Groove Design Sealing Australia

Fundamental Of O Ring

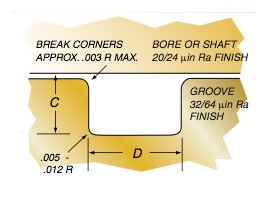

Groove Design Technical Data Static ORing Axial (Face Seal) Glands Gland Squeeze Groove Width Groove;Oring seal The tables at the right and the diagram below provide the recommended gland design parameters In addition, the gland surfaces must be free from all machining irregularities, and the gland edges should be smooth and true and free of nicks, scratches, and burrs A perfectly designed Oring seal is of little use if the OringGland Design for Static Application for Orings with Axial Squeeze Surface Finish X groove top and bottom for liquids X = 32 micro inches (08 μm Ra) • Gland Dimensions Static ApplicationFace Seal GlandsMetric W Oring Cross Section E Gland Depth F

O Ring Groove Design Guides Engineering Quick Reference

What You Need To Know About Designing Axial Seals Hot Topics

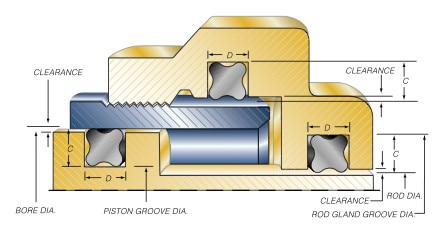

Oring seals are typically used for sealing spool valves and for pistons in pneumatic cylinders and similar reciprocating applications Two regimes are possible • With radial compression of the Oring The ring is compressed radially in its groove, with a compression of the crosssection of from 2% to 6%, according to thicknessORing Groove Design 1 The following sizes are not normally recommended for dynamic service, although special applications may permit their use 2 Clearances shown are based on 70 durometer materials The clearances must be held to an absolute minimum consistent with design requirements for temperature variations and should not exceed the(ORing C/S) Gland Depth / (ORing C/S) Face seal30% Static Male/Female 15% Reciprocating 10% Rotary 010% ORing Installed Stretch (Groove Diameter) (ORing ID)(ORing ID) General rule is 05% Excessive stretch can overstress material, thin cross section, and reduces % squeeze % cross section reduction due to stretch about

O Ring Groove Drafting Standards Gd T Tolerance Analysis Eng Tips

Fep O Rings Trelleborg Sealing Solutions

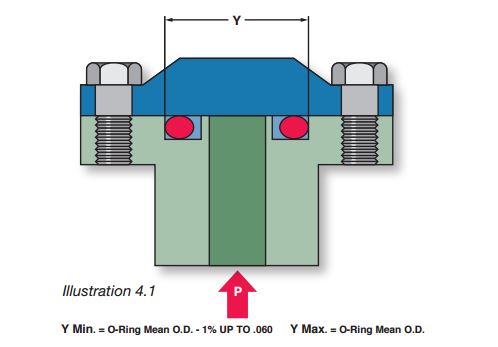

AS568B STANDARD ORING GROOVE DESIGN Contact Us For Assistance Or Samples Click Here and contact us today to receive a quote or if you have any questions regarding sizing × Dismiss alert The three main types of standard groove designs are Industrial Static also called Radial, Industrial Reciprocating also called Dynamic, and Face Seals also43 Face Type Seals Design Chart 43 explains how to design an Oring seal when the groove is cut into a fl at surface Note that when the pressure is outward, the groove outside diameter (OD) is primary and the, groove width then determines the inside diameter Conversely, when the pressure is inward, the groove inside diameter is primary Here are 4 commonly made mistakes when designing an oring axial face seal Gland height is not the same as groove depth Most oring face seal applications have a groove designed into one of the mating hardware components The geometry of the groove is important – the dimensions need to be specific because the oring is located in the groove

O Ring Groove Design Guides Engineering Quick Reference

O Ring Groove Dimensions Calculator Precision Polymer Engineering

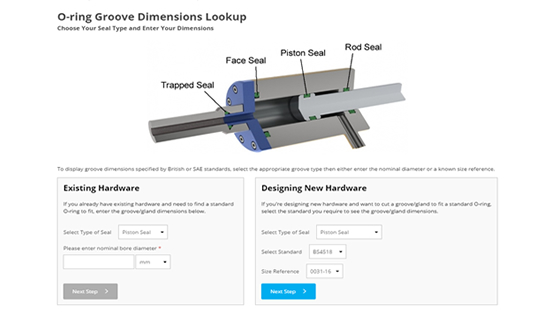

The face seal design chart below explains the hardware dimensions to use for an Oring seal when the groove is cut into a flat surface For designing systems which contain internal pressure, like the example below, the groove's outside diameter (OD) is primary, and the groove's width then determines the inside diameterIf you are designing a face seal, select the QuadRing® Brand with an inside diameter which will position the QuadRing® Brand on the side of the groove opposite the pressure Click here for more information on face seal groove design Note the QuadRing® Brand inside diameter for the next step Calculate the Seal StretchOring Groove Design in 3 easy steps Step 1 Choose whether you are working with existing hardware or designing new hardware Select the type of Oring groove piston, rod, face seal or trapped seal If the Oring size required is known, simply select the AS, BS or ISO standard (such as AS568) and enter the dash size reference

Face Seal Wikipedia

O Ring Groove Design Standard As568b Seal Design Inc

Metric oring groove designs vary greatly and choosing the right one for your application is important for maximum oring performance This metric oring groove design reference guide will help you find the right radius, backup, pressure and other oring dimensions for basic applicationsDovetail grooves are used to hold the Oring inplace on a face seal groove during during assembly and maintenance of equipment An undercut or dovetail groove has proven beneficial in many applications to keep the oring in place However, this is an expensive groove to machine, and thus should be used only when absolutely necessaryParker's SealLok ORing Face Seal Hydraulic Hose Fittings and Adapters ( also known as ORFS) are valued across many markets for excellent leak protection and unlimited reusability* Parker's patented captive Oring groove (CORG) design guarantees optimal sealing and ensures Oring retention before the final assembly ORFS meet or exceed

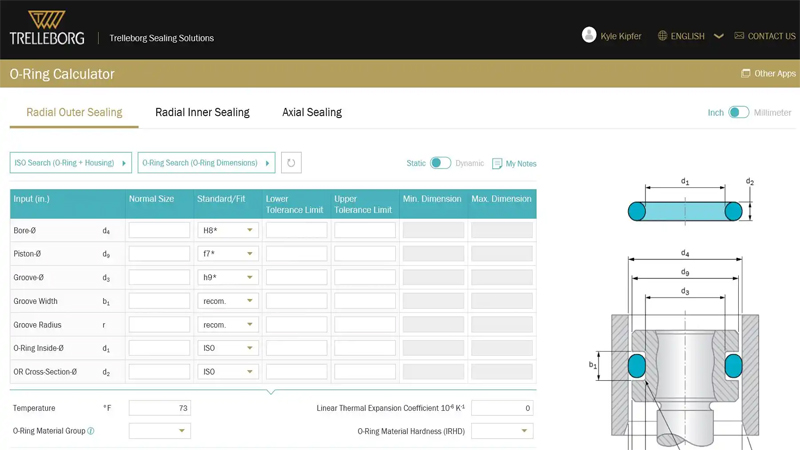

O Ring Calculator Trelleborg Sealing Solutions

Static O Ring Sealing Sealing Devices Inc

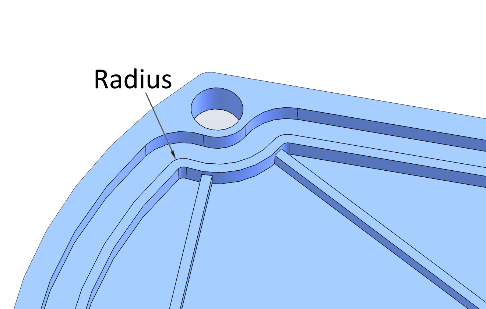

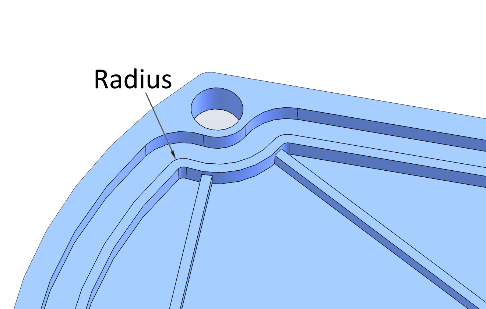

The oring gland design is very simple for face seals Simply cut out a circular groove into one of the plates and leave the other plate completely flat, the groove will have a square/trapezoidal cross section and the dimensions are conveniently already calculated and laid out in tables in the Parker Oring Handbook A noncircular face seal footprint might also be called a racetrack groove, a wandering groove or a custom plan view When using an Oring, the main design consideration is the corner or smallest radius (shown "r" in diagram) The inside radius should be at least three times the Oring cross sectional diameter A static face seal type oring seals against the groove at the top and bottom points of contact If you calculate the amount of friction force holding the oring in place, created by compressing the oring over its linear length, you'll be surprised at how much pressure differential it would actually take to push the oring out against one side

Oring Ehandbook

Groove Design O Ring Seals Minnesota Rubber Plastics

Dovetail grooves are used to hold the Oring inplace on a face seal groove during during assembly and maintenance of equipment An undercut or dovetail groove has proven beneficial in many applications to keep the oring in place However, this is an expensive groove to machine, and thus should be used only when absolutely necessaryCustom material development and design are typically available at no cost Exceptional Service Communicate directly with our dedicated team of experienced professionals empowered to find creative ways to deliver service solutions Typical office hours MF 0am5pm EST and we respond to email in hours if not minutesThe Oring calculator tool is intended to form the basis of an oring installation, and assist with selection of oring and hardware dimensions Recommendations are based on available technical information, and are offered as suggestions only, any reliance placed on such information by the user is strictly at the user's risk

O Rings An Overview Sciencedirect Topics

Groove Design Quad Ring Seals Minnesota Rubber Plastics

Square Rings fit in oring grooves and are interchangeable sizeforsize Square Rings are available in a variety of rubber and plastic materials such as NBR, Viton, EPDM, Teflon, etc In most static applications, a Square Ring will serve as a direct replacement for an oring and generally will perform a highpressure sealing function as wellParker's Oring Face Seal (ORFS) Tube Fittings and Adapters, SealLok, meet or exceed the requirements of both SAE J1453 and ISO and have international acceptance Oring face seal fittings offer zero clearance, resistance to over torque and vibration resistance making it an ideal reusable hydraulic fitting solution across many markets1 Male or Plug the Oring groove is located on a plug which is inserted into the housing or cylinder (fig 123) 2 Female or Tube the Oring groove is located in the housing or cylinder and a tube is installed through the Oring lD (fig 124) Male or Plug Seal design is based on the following factors (refer to fig 123) Bore

Designing Axial Static O Ring Grooves To Industry Standards Grabcad Tutorials

Buna O Ring O Ring In Houston And Minneapolis Dichtomatik

Dovetail ORing Gland Design In a dovetail oring gland application the oring squeeze is primarily axial in direction, where a valve exerts force on the top and bottom of the orings surfaces Typically used in static or slow moving applications the dovetail orings gland purpose is to properly hold the oring in place during machine operationDesign Chart 7 shows the groove width necessary to accommodate the thickness of the backup rings Teflon backup rings are usually furnished in An Oring seal is required for this piston First Find ring sizes whose OD is close to 1000" (I117, I210) Second Check the swell characteristics of the liquid being pumped (AcetoneSTATIC FACE OR FLANGE ORING SEALS INTERNAL PRESSURE design is based upon the groove OD to limit the side movement in the groove due to pressure direction Figure 25 shows a diagram for a face seal designed for internal pressure Grooved OD (outside diameter Y) Groove Depth;

How To Design An O Ring Groove Vizeng

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

For a face seal, use the clearance determined in Step 2 and read its value directly from the graph Calculate the seal groove dimensions Using either the QuadRing® Brand table or the ORing table, determine the groove width "D" for the seal crosssection size you have selected Determine the seal groove diameter as described in theIt is sometimes necessary to add a retention feature to a face seal gland The result is a dovetail and halfdovetail This shape may also be called an undercut It should be noted that although this method has been used successfully, it is not generally recommended The inherent characteristics of the groove design limit the amount of void areaERIKS standard ORings and load them also into your created design info chemical volume swell (%) cross section diameter (mm) ISO 3601 free Calculate Results Reset calculator

O Ring Design Considerations Marco Rubber Plastics Custom O Rings Supplier

O Ring Info En O Ring Oring Handbook Eriks Sealingelements Technicalhandbook O Rings Oringapplications Pdf

O Ring Groove Design O Ring Groove Dimensions Mykin Inc

Oring Ehandbook

O Ring Design Considerations Marco Rubber Plastics Custom O Rings Supplier

Groove Design O Ring Seals Minnesota Rubber Plastics

O Ring Groove Design Guides Engineering Quick Reference

O Ring Groove Design Sealing Australia

O Ring Cross Section O Ring Groove Design Data

O Ring Groove Design Global O Ring And Seal

Design Of Oring Seals Design Of Oring Seals

O Ring Groove Design Global O Ring And Seal

O Ring Design Considerations Marco Rubber Plastics Custom O Rings Supplier

O Ring Groove Design Guides Engineering Quick Reference

What Are Static Seals Hot Topics

Www Applerubber Com Src Pdf Seal Design Guide Pdf

4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics

Parker S O Ring Selector App Youtube

How To Design An O Ring Groove Vizeng

O Ring Calculator Ceetak Sealing Solutions

How To Design An O Ring Groove Vizeng

2 Design And Detail Information O Rings Stock O Ring Webshop

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

Design Of Oring Seals Design Of Oring Seals

Quad Ring Groove Design Daemar Inc

How To Design An O Ring Groove Vizeng

O Ring Groove Design Daemar Inc

O Ring Groove Design Global O Ring And Seal

Static O Ring Groove Design A Rod And Piston Glands

Groove Design Gland Design O Ring Groove Gland Design

Groove Design Gland Design O Ring Groove Gland Design

4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics

How To Use An O Ring In A Non Circular Groove Pattern

O Ring Groove Design

Untitled Document

-due-to-stretch.gif)

Oring Ehandbook

Mating Ring An Overview Sciencedirect Topics

O Ring Groove Design Standard As568b Seal Design Inc

Seals Eastern Flange Seal O Ring Design Guideline

The Different Between O Ring Boss And O Ring Face Sealing Sae Fittings Youtube

Ficient Design Static O Ring Groove Design Mechanical Engineering

O Ring Groove Design Global O Ring And Seal

Oring Ehandbook

Static O Ring Face Seal Groove Design Guide

O Ring Seals Roy Mech

4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics

Jehbco S O Ring Design Articles Jehbco Silicones

1

O Ring Groove Design Global O Ring And Seal

Dovetail O Ring Groove Design Guide A Basic Recommendations

Metric O Ring Groove Design Reference Guide

O Ring Groove Design Sealing Australia

Sae J1453 O Ring Face Seal Groove Size Chart Knowledge Yuyao Jiayuan Hydraulic Fitting Factory

Groove Design Quad Ring Seals Minnesota Rubber Plastics

Quad Ring Face Seal Application Example Minnesota Rubber Plastics

O Ring Groove Design Standard As568b Seal Design Inc

Jehbco S O Ring Design Articles Jehbco Silicones

Groove Design Gland Design O Ring Groove Gland Design

Dynamic O Ring Groove Design Guide A Rod And Piston Glands

O Ring Groove Design Metric Seal Design Inc

Design Of Oring Seals Design Of Oring Seals

2 Design And Detail Information O Rings Stock O Ring Webshop

O Ring Groove Design Global O Ring And Seal

Oring Ehandbook

O Ring Groove Design Dovetail Seal Design Inc

Groove Design Gland Design O Ring Groove Gland Design

4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics

O Ring Groove Design Seal Design Inc

Types Of O Ring Applications

O Ring Dimensions

How To Design An O Ring Groove Vizeng

Seals Eastern Plug Seal O Ring Design Guideline

Static O Ring Face Seal Groove Design Guide

1

Groove Design O Ring Seals Minnesota Rubber Plastics

Static O Ring Face Seal Groove Design Guide

O Ring Wikipedia

American Seal Packing General Design And Gland Dimensions

O Ring Groove Design Global O Ring And Seal

O Ring Groove Dimensions Calculator Precision Polymer Engineering

No comments:

Post a Comment